A Comprehensive Guide to the Leading Manufacturer of Heat Exchangers

Introduction

Manufacturers of Heat Exchangers play an essential duty in handling heat transfer processes in countless commercial setups. Whether it’s for cooling systems in power plants, home heating applications in chemical markets, or preserving ideal temperatures in food handling units, the demand for trusted and reliable تولید کننده انواع مبدل های حرارتی is ever-growing. AGEN sticks out as a premier manufacturer, providing a diverse series of heat exchanger designed to deal with the one-of-a-kind needs of each application.

Comprehensive Range of Heat Exchangers

Washer Plate Heat Exchangers

Washing machine plate Manufacturers are known for their durable style and high thermal performance. These exchangers contain a collection of plates that develop numerous networks for liquid circulation, improving heat transfer capacities. AGEN’s washer plate heat exchanger are diligently crafted to ensure maximum performance, making them excellent for sectors where room and performance are essential.

Put Heat Exchangers

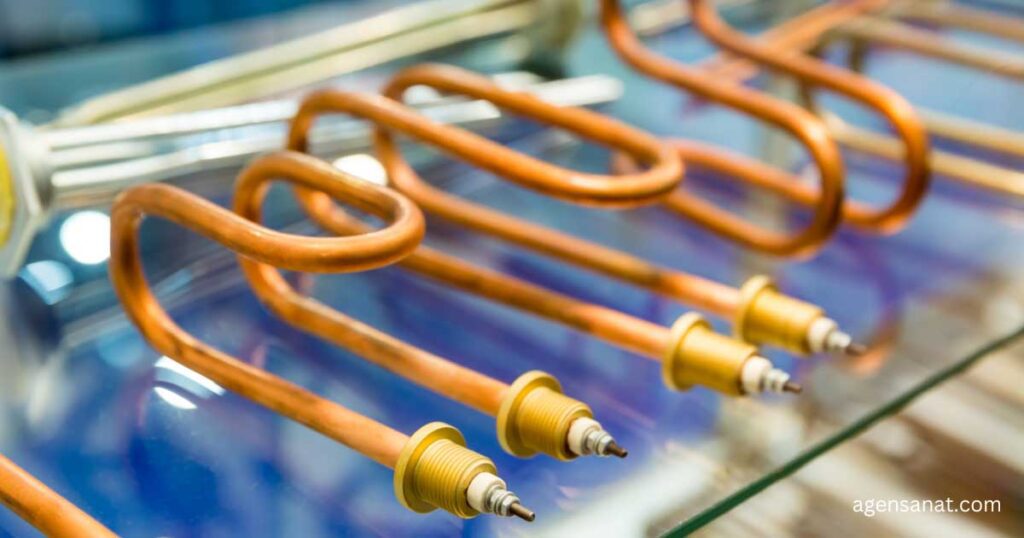

Put heat exchangers, additionally referred to as shell and tube Manufacturers of Heat Exchangers, are amongst the most typical types used in various markets. They include a collection of tubes, one set for the hot liquid and an additional for the cold fluid, enclosed within a round covering. AGEN’s heat exchangers are developed to manage high pressures and temperature levels, making them suitable for applications that require them.

Pillow Plate Heat Exchangers

Cushion plate Manufacturers of Heat Exchangers are innovative remedies made for applications requiring efficient heat transfer with minimal space requirements. These exchangers include a special pillow-like structure created by two plates welded together and blown up to develop a collection of networks for liquid circulation. AGEN’s cushion plate heat exchanger are perfect for sectors like food and drink, where health and performance are vital.

Welding and Semi-Welding Heat Exchangers

Welding and semi-welding Manufacturers of Heat Exchangers are developed for applications needing robust building and high performance. These exchangers are partially or completely welded, offering premium durability and leak-proof procedure. AGEN provides a series of welding and semi-welding heat exchanger tailored to fulfill the extensive needs of markets such as petrochemical, oil and gas, and power generation.

Why Select AGEN for Heat Exchangers?

AGEN’s commitment to top quality, development, and complete client satisfaction sets it apart as a leading manufacturer of heat exchangers. Right here are some reasons that AGEN is the preferred choice for numerous sectors:

1. Expertise and Experience: With years of experience in the market, AGEN has actually developed unmatched expertise in designing and making heat exchanger.

2. Personalized Solutions: AGEN works very closely with clients to understand their detailed needs and supply personalized remedies that meet their precise needs.

3. Quality control: Every item goes through extensive screening and quality checks to guarantee it satisfies the highest requirements of performance and dependability.

4. Innovative Modern technology: AGEN continuously invests in research and development to incorporate the most recent technical innovations into its products.

5. Customer Support: AGEN supplies thorough support throughout the lifecycle of its items, from setup and appointing to maintenance and troubleshooting.

Applications of AGEN Heat Exchangers

AGEN’s Manufacturer of Heat Exchangers discovers applications across a vast array of sectors, each with its unique requirements and difficulties. Below are some essential markets where AGEN’s products are making a substantial impact:

Heating, cooling, and Refrigeration

In the HVAC and refrigeration field, efficiency and integrity are crucial. AGEN’s heat exchanger are created to enhance thermal administration, making sure regular efficiency in home heating, ventilation, and cooling systems. The compact design and high performance of washing machine plates and cushion plates Manufactured by Heat Exchangers make them perfect for these applications.

Chemical and Petrochemical Industries

The chemical and petrochemical markets demand durable and resilient devices capable of handling harsh materials and high temperatures. AGEN’s put and welding Manufacturers of Heat Exchangers are developed to withstand these rough conditions, providing reputable heat transfer solutions for processes such as purification, condensation, and heat healing.

Food and Drink Handling

Preserving hygiene and exact temperature level control are important in the food and drink sector. AGEN’s cushion plate heat exchangers are specifically developed to meet these demands, ensuring effective heat transfer while adhering to stringent health standards. These exchangers are extensively used in applications like pasteurization, fermentation, and cooling.

Power Generation

Power plants need effective thermal monitoring systems to enhance power production and reduce waste. AGEN’s variety of Heat Exchanger manufacturers, including pour and welding types, are crafted to handle the high pressures and temperature levels related to power generation. These exchangers play an important duty in processes such as vapor generation, cooling, and heat healing.

Renewable Energy

As the world moves towards renewable energy resources, the requirement for reliable heat transfer services becomes increasingly important. AGEN’s heat exchangers are used in various renewable energy applications, including solar thermal systems, geothermal power plants, and bioenergy production. The convenience and performance of AGEN’s products make them optimal for using and managing renewable resources.

Conclusion

Picking the appropriate heat exchanger is crucial for maximizing thermal management in numerous commercial applications. As a leading manufacturer of heat exchangers, AGEN supplies a comprehensive series of products made to meet the diverse needs of various fields. With a dedication to top quality, development, and consumer contentment, AGEN remains to set the criterion in the heat exchanger industry, giving trustworthy and effective options that drive operational excellence.

FAQs

1. What kinds of heat exchangers does AGEN manufacture?

AGEN manufactures a wide array of heat exchanger including washer plate heat exchanger, pour heat exchanger, pillow plate heat exchanger, and welding and semi-welding heat exchanger.

2. What markets make use of AGEN heat exchangers?

AGEN, Manufacturer of Heat Exchangers, is used in various industries such as cooling and heating and Refrigeration, chemical and petrochemical, food and beverage processing, power generation, and renewable energy.

3. Exactly how do pillow plate heat exchangers vary from various other kinds?

Cushion plate heat exchangers feature a distinct style. Two plates are bonded together and inflated to produce channels for fluid flow. This design maximizes the area for efficient heat transfer and is especially suitable for sanitary applications like food and drink handling.

4. What are the advantages of using welding and semi-welding heat exchanger?

Welding and semi-welding heat exchangers provide exceptional toughness, watertight procedure, and high stamina, making them optimal for applications entailing high pressure and temperature conditions.

5. Just how does AGEN ensure the high quality of its heat exchangers?

AGEN employs strenuous screening and quality control procedures throughout the manufacturing procedure to guarantee that all products fulfill the highest possible criteria of performance and integrity.

6. Can AGEN supply tailored heat exchanger options?

Yes, AGEN functions closely with customers to comprehend their detailed needs and supply tailored Manufacturers of Heat exchanger solutions that fulfill their exact needs.

Leave a Reply